Product Catalog

Paddle mixer

Paddle mixer type: MFK with column loading for 200l stuffing trolleys

Application:

The paddle mixer is designed for mixing stuffing in meat, sausage, delicatessen, fish, fruit and vegetable and confectionery plants.

Design:

Stable and robust construction – internally polished tank made of EN 1.4301/1.4307 stainless steel. The device utilizes a double mixing system that allows for thorough and even mixing of all filling ingredients. The hygienic and ergonomic design ensures easy operation, cleaning, and maintenance. A wide range of applications thanks to the specially designed bowl and paddles. High-quality components.

Mixing:

The versatile system of overlapping mixing shafts is suitable for a wide range of mixed products

Control:

The Pro-face controller with a 5.7" touchscreen allows you to program 6 mixing cycles with variable speed and direction. Monitors all sensors and displays the current position of moving parts. In the event of a malfunction, errors and possible causes are displayed.

Seals:

The mixer uses modern fast-split gasket seals. Replacing the seal takes just minutes.

Additional equipment for the mixer:

• Automatic water dosing system

• Free-standing service platform

• Weighing system

• Vacuum system

• Elevated machine for unloading into big box containers

Tilting Cooking Boiler

Application: Tilting cooking boiler is used for scalding, cooking and lard melting.

Construction: Construction is made of stainless steel, dual-jacket heating system assures uniform charge temperature, it protects from product burning and it guarantees small required amount of energy. Features: microprocessor control to adjust: batch temperature, oil jacket, a temperature sensor (the bar), the time operation of the boiler, the autostart function. Insulated floor, side walls, lid.

Variants of heating: electric

Please note! Devices are constantly upgrading, so the specifications, dimensions and weight may be different from values given in the table. Dimensions and weights are approximate and can not be the basis for design purposes or shipping. We provide details in the case of purchase.

Vacuum Massager type: MK

Application: Tumbler is designed for vacuum plasticizing different kinds of meat during curing in the production of meat and smoked meat. Multichamber drums provide massage different products in one device. Through the use of cooling massaging drum it is possible to reduce the massaging time while improving the quality of manufactured products. Loading batch can optionally be mechanized.

Features: microprocessor controller, programmable functions: autostart, massaging drum speed, working time, break time, total time of massaging, vacuum degree for each massaging phase, the temperature of batch for tumblers with cooling. The patented system of batch cooling and multichamber massaging drum.

Rules of functioning: Meat assigned to pickling and massaging is loaded to tank with pickling mixture. After pumping air out of tank and programming of parameters of technological process, process of massaging starts. After massaging meat falls down gravitationally to placed container.

Caution! Loading of the charge to 70% capacity of the tank. The multichamber vacuum tumbler is adjusted manually.

Vacuum Massager type: MKL

Application: Tumbler is designed for vacuum plasticizing different kinds of meat during curing in the production of meat and smoked meat. In obliquely lying drum there are used three spiral-shaped blades massaging. Unloading of charge takes place after start of rotation in the opposite direction to the direction of massaging. Through the use of cooling massaging drum it is possible to reduce the massaging time while improving the quality of manufactured products. Loading batch can optionally be mechanized.

Features: microprocessor controller, programmable functions: autostart, massaging drum speed, working time, break time, total time of massaging, vacuum degree for each massaging phase, the temperature of batch for tumblers with cooling. The patented system of batch cooling and.

Caution! Loading of the charge to 70% capacity of the tank.

Pickle Injector for Red and Poultry Meat type: NK

Application: Pickle injector is appliance designed to intramuscular induction of pickling brine into meat with bone or into meat without bone.

Features: depending on the destination, the injectors are equipped with the appropriate tooling:

– stainless steel conveyor to the red meat or plastic conveyor to the poultry meat.

– rotary pump or centrifugal pump,

– one set of needles Ø 4 mm,

– brine tank with filters system.

Optionally injector can be equipped with a mechanical drum-type slot filter: FNK.

Manually controlled Injector [type: NK] is equipped with a touch screen PROFACE, to control the following parameters:

– speed of the injection column;

– pitch of the conveyor (puncture density);

– brine pressure regulation;

– controlling and stopping the device in the absence of brine in the tank or lack of phase on the electrical supply,

– indication of the cause of stopping the device;

Manually:

– adjusting the height of bumper lift;

– needles mounted on the quick connector.

Microprocessor-controlled injector [type: NK-K] is equipped with a touch screen PROFACE to control the following parameters of injection (the ability to save technological programs):

– speed of the injection column;

– pitch of the conveyor (puncture density);

– injection pressure regulation;

– preview of brine temperature;

– adjusting the height of bumper lift;

– moment of injection of brine in meat;

– control and stopping of the device in the absence of brine in the tank or lack of phase in the electrical supply;

– indication of the cause of stopping the device;

– operating time counter;

In the injector are used quick changeable needles:

– single Ø4 mm, for injection of red meat on the bone or boneless;

– double 2x Ø3 mm, for injection of poultry meat on the bone or boneless;

– quad 4x Ø2 (Ø1,65) mm, for injection culinary meat without bones;

– Single Ø4 mm, for very thick emulsion injection.

Tilting cooking boiler with a mechanical mixer, type: KKmU

Application: Cooking boiler is used for melting fat, the production of ketchup, cooking products.

Construction: Boiler construction is made of acid resistant steel. Two-jacket heating system protects from product burning. Teflon scraper in mixers clean thoroughly boiler surfaces during cooking.

Equipment: microprocessor control of: product temperature, oil jacket temperature, time of operation of the boiler, the autostart function. Agitator finished with teflon scrapers, insulated construction, water inlet .

Variants of heating: electric

Round section cooking boiler with mechanical mixer type: KKm

Application: Cooking boiler is used for melting fat, the production of ketchup, cooking products.

Construction: Boiler construction is made of acid resistant steel. Two-jacket heating system protects from product burning. Teflon scraper in mixers clean thoroughly boiler surfaces during lard melting.

Equipment: microprocessor control of: product temperature, oil jacket temperature, time of operation of the boiler, the autostart function. Agitator finished with teflon scrapers, insulated construction, discharge of steam, water inlet, drain valve ended – knee .

Variants of heating: electric, gas burner, oil burner or steam heating [max. pressure – 0.5 bar].

Small Cooking Boiler; with oil-jacketed, type: KK/e

Application: Cooking boiler is used for scalding, cooking and lard melting.

Construction: Construction is made of stainless steel, dual-jacket heating system assures uniform charge temperature, it protects from product burning and it guarantees small required amount of energy.

Features: microprocessor control to adjust: batch temperature, oil jacket, a temperature sensor (the bar), the time operation of the boiler, the autostart function. Insulated floor, side walls, lid, drain, water inlet are standard facilities.

Variants of heating: electric,

Please note! Devices are constantly upgrading, so the specifications, dimensions and weight may be different from values given in the table. Dimensions and weights are approximate and can not be the basis for design purposes or shipping. We provide details in the case of purchase.

Hydraulic tipper

Zastosowanie

Urządzenie służy do wyładunku produktu umieszczonego w skrzynio- palecie.

Budowa urządzenia

Urządzenie jest maszyną stacjonarną, umieszczoną na stopach. Konstrukcja wykonana jest ze stali nierdzewnej 1.4301/1.4307, dopuszczonej do kontaktu z żywnością. Maszyna napędzana jest hydraulicznie.

Pickle Injectior for Fish type: NKR

Application: Injector type: NKR is a device for injection fish fillets and fish parts with brine solution or a thick emulsion.

Features:

– plastic conveyor,

– rotary pump or centrifugal pump,

– one set of quadruple needles 4x Ø1,65 mm,

– brine tank with filters system.

Optionally injector can be equipped with a screw pump [type: NKR-s] and rottary drum slotted filter type: FNK. This equipment allows the injection of a very thick emulsion.

Manually controlled Injector [type: NKR] is equipped with a touch screen PROFACE, to control the following parameters:

– speed of injector frame;

– controls and stops operation in the absence of the brine container or the absence of electrical phase flow, indicating the reason for stopping the machine;

Manual adjustment:

– Stepless adjustment of the belt stroke;

– injection pressure;

– height of bumper rise; Needles mounted on quick coupler.

Microprocessor-controlled injector [type: NKR-K] is equipped with a touch screen PROFACE to control the following parameters of injection (the ability to save technological programs):

– speed of injector frame;

– speed of the belt;

– move of belt (density of punctures);

– height of bumper rise;

– moment of injection brine in the meat; – pressure of brine;

– brine temperature control;

– stop operation in the event of failure, indicating its location;

– indicate the causes of failure;

– operating time counter;

– stop operation in the absence of brine in the tank.

Mobile column loader; type: EUZ

The loading column is designed to work with various butchering devices that require loading the raw material with a 200l stuffing trolley. The lift is mobile, it has the possibility of adjusting the height of the hopper and the lifting height.

Universal Cooking Boiler type: KK

Application: Cooking boiler is used for scalding, cooking and lard melting.

Construction: Construction is made of stainless steel, dual-jacket heating system assures uniform charge temperature, it protects from product burning and it guarantees small required amount of energy. Features: microprocessor control to adjust: batch temperature, oil jacket, a temperature sensor (the bar), the time operation of the boiler, the autostart function. Insulated floor, side walls, lid, drain, water inlet are standard facilities. Boiler dimensions and equipment can be adapted to individual needs.

Variants of heating: electric, gas burner, oil burner or steam heating [max. pressure – 0.5 bar].

Optional equipment: cover lifted pneumatically, shelves for storing smoking bars, baskets with opening bottom, the lifting device type: “crane” or gantry.

Please note! Devices are constantly upgrading, so the specifications, dimensions and weight may be different from values given in the table. Dimensions and weights are approximate and can not be the basis for design purposes or shipping. We provide details in the case of purchase.

High Efficiency Injector with Screw Pump type: NK-s

Appl ication: Pickle injector is appliance designed to intramuscular induction of pickling brine into meat with bone or into meat without bone. Special screw pump can inject pickling brine and dense pickling emulsion.

Features: depending on the destination, the injectors are equipped with the appropriate tooling:

– stainless steel conveyor to the red meat or plastic conveyor to the poultry meat.

– screw pump – to inject brine curing or very dense emulsion,

– one set of needles Ø 4 mm,

– brine tank with filters system.

Optionally models NK-s can be equipped with a mechanical drum-type slot filter: FNK.

Manually controlled Injector [type: NK-s] is equipped with a touch screen PROFACE, to control the following parameters:

– speed of the injection column;

– pitch of the conveyor (puncture density);

– brine pressure regulation;

– controlling and stopping the device in the absence of brine in the tank or lack of phase on the electrical supply,

– indication of the cause of stopping the device;

Manually:

– adjusting the height of bumper lift;

– needles mounted on the quick connector.

Microprocessor-controlled injector [type: NK-sK] is equipped with a touch screen PROFACE LM4200 to control the following parameters of injection (the ability to save technological programs):

– speed of the injection column;

– pitch of the conveyor (puncture density);

– injection pressure regulation;

– preview of brine temperature;

– adjusting the height of bumper lift;

– moment of injection of brine in meat;

– control and stopping of the device in the absence of brine in the tank or lack of phase in the electrical supply;

– indication of the cause of stopping the device;

– operating time counter;

In the injector are used quick changeable needles:

– single Ø4 mm, for injection of red meat on the bone or boneless;

– double 2x Ø3 mm, for injection of poultry meat on the bone or boneless;

– quad 4x Ø2 mm, for injection culinary meat without bones;

– Single Ø4 mm, for very thick emulsion injection.

Gourmet Food Vacuum Tumbler type:MKLg

Application: Tumbler has universal application – with easy replaceable blades, can be used to vacuum plasticization different types of meat, meat processing, the delicatessen, restaurants, also for mixing herbs, spices, salad, salads, meat stuffing, etc.

Construction: Construction of the tumbler is made of stainless steel. Tumbler tank is removable and can be moved for construction purposes. The drum lying obliquely massage uses 2 sets of spiral-shaped blades – to massage or mixing products. The drum is equipped with a massage in a comfortable hermetic and transparent cover for easy observation of the process of massaging or mixing. Unloading is mechanically load after starting the rotation of the drum in the opposite direction. Drum speed is continuously adjustable and can be set to cycle to the left and right sides, the length of cycles continuously adjustable.

Advantages:

loading charge to 70% by volume;

ease of maintaining hygiene;

replaceable blades enable universal use of the device;

possibility to observe process during operation.

Scalding – Dehairing Machine type: OSK

Application: Scalding dehairing machine is used in process of slaughter to scalding and mechanical dehairing of hog carcass weighing up to 300 kg.

Construction: Construction and outside casing are made totally of acid-resisting steel.

Working part consists of scalding machine and power and steering parts. Inside of scalding machine there are assembled two-jacket heating system, two dehairing drums and appliance for throwing outside hog carcass. Scalding machine posses two covers that enables front and back carcass loading. On side of scalding machine there is assembled comfortable bristle separator.

Variants of heating: electric, gas burner, oil burner or steam heating [max. pressure – 0.5 bar].

Dripping tunnel / Continous draining tumbler

Principle of operation: The drip tunnel is a device that separates the excess brine while closing the needle holes formed after the injection process of meat and poultry elements.

Brine Mixer type: MSPK

Application: The mixing of brine is used to produce a homogeneous solution of brine. The resulting solution can be used in the processes of meat processing (eg,njections).

Construction: The mixer is a device detached brine made of stainless steel. The device consists of the following elements: a tank (with chute), mechanicalstirring, mixing/transporting pump, loose material hopper, distribution pipe with valves, control box. Mixing the solution is done using a mechanical agitator and through circulation of the brine.

Flake Ice Generator type: WLK

Application: Flake Ice Generator is used for producing ice in flake forms. Flakes with temperature of about –9⁰ C and width of 0,8 mm are ideal for use in meat processing appliances and as coolers.

Construction: Flake Ice Generator is free-standing appliance, made of acid-resistant steel, with cooling unit built-in or installed outside of casing.

Features: Automatic protection against excessive ice in the container, the lack of water supply, phase failure.

Cheese cube machine

Application: slicer is used for cutting blocks of cheese with maximum dimensions: Width-400 mm, height-300 mm, and cheese in the shape of a cylinder with a maximum diameter 100 mm, for cube measuring 5x5x5 cm. This allows, in turn, other devices to form a shavings. Used, among others for the production of pizzas, baguettes, cheese blocks.

Construction and operation: The design of the device is made of stainless steel.

The device consists of two units:

Unit of conveyor feeding;

Horizontal cutting section – transverse unit of knives, powered by a hydraulic cylinder;

Vertical cutting section – guillotine powered by a hydraulic cylinder;

Hydraulic system;

Electrical control;

The device works automatically. Cycle of action:

Conveyor moves the blocks of cheese with a preset distance (10 to 200 mm)

Vertical cutting section cut from blocks of pre-programmed slice thickness

Horizontal section cut transversely cut off slice into cubes 50x50x (10-200) mm

Cheese cut into cubes falls to dump raw gutter.

Back to Action 1

Buggy washer type: MSKc-25

Application: The machine is used to wash stuffing trolleys (200 liters) up to 25 pcs/hr. Provides highly effective cleaning and disinfection.

Variants of heating: electric, gas burner, oil burner or steam heating [max. pressure – 0.5 bar].

Structure: The structure is made of stainless steel. Two-mantle wash water heating system with a closed water circulation. The device consists of a washing and rinsing chamber with rotating spray arm and nozzle system and cover – lift, which transports trolley into the chamber.

Advantages:

automatic dispensing of detergent;

low energy consumption;

water savings;

High efficiency washing;

high durability and reliability of the heating units;

multilevel security system in operating the equipment and the cleaning process;

loading and unloading mechanism;

closed circuit of water with filtration system;

complete programming and controlling of the cleaning process phases .

Universal Passage Washing Machine for Plastic Crates type: MSK

Application: Device is designed for automatic washing of standard plastic crates, based on a rectangular 600×400 mm and a height up to 420 mm, and for washing covers of such containers and pallets.

Construction: Construction of appliance is made of acid-resisting steel. Two-jacket heating system of washing water with closed water cycle. W

Variants of heating: electric, gas burner, oil burner or steam heating [max. pressure – 0.5 bar].

Principle: Transport of containers performs mechanically. Washing in standard machine performs in two stages:

principal washing (hot water with washing agent addition)

final rinsing (with flowing water)

Rotary slotted drum filter type: FNK / with cooling system type: FNK-c

Purpose: The drum filter is used to separate solid contaminants from the liquid, eg. from brine. Works with Injectors type: NK and Brine mixers type: MSPK. The filter is also available in a version with a cooling system type: FNK-250c.

Principle: Solids are removed from the liquid during the flow ofliquid through the rotary drum filter, and a team of differentgradation screens.

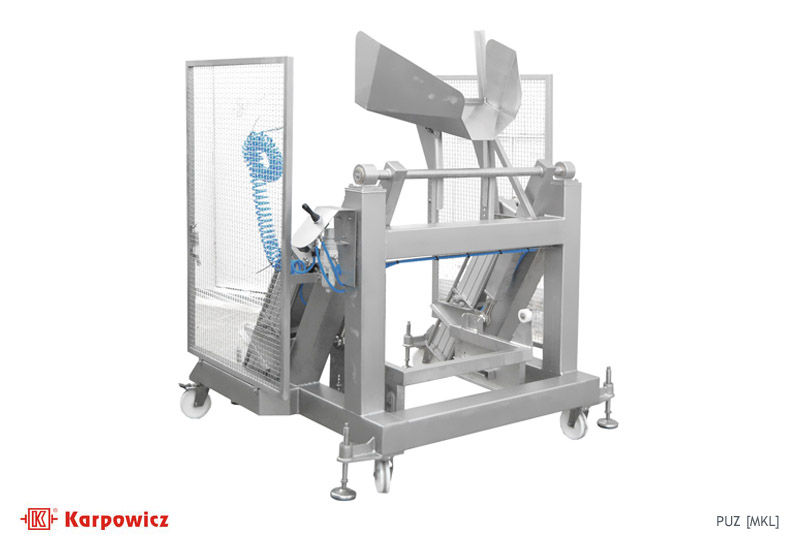

Pneumatic loading device type: PUZ

Application: Pneumatic lift is used to pre-load of meat placed in the wheelchair 200 l into the desired device.

Principle of operation: Pneumatic actuators motion raises a loaded truck 200 l. Meat after lifting truck is gravitationally loaded to the desired device.

Construction: The unit is placed on the mobile machine wheels with brakes. The design is made of stainless steel, approved for food contact. The machine is powered by compressed air.

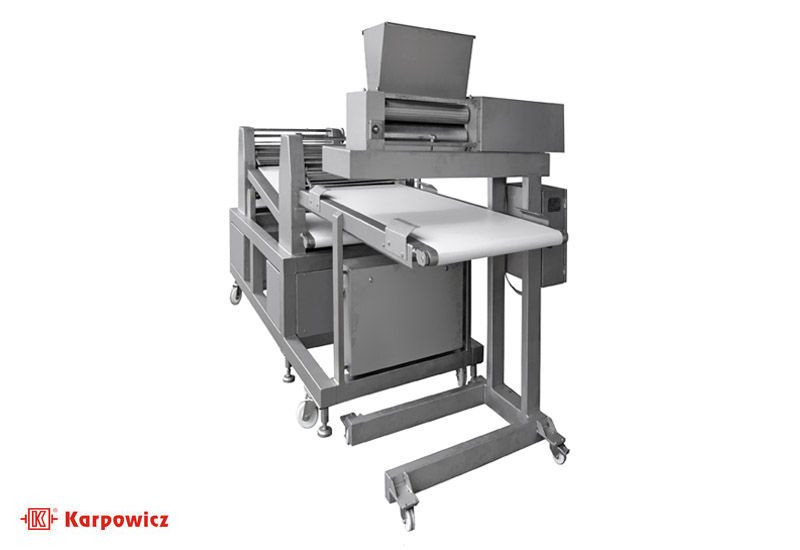

Food products dosing machine

Appliance: Food stuff batcher is a machine composing part of a line for belt-system pizza production. This device is assigned for pouring shredded food products, at a uniform rate, on the surface of pizza bases that are moved by straight belt conveyor*.

Principle of operation: The machine spreads the food product on the feeding conveyor by means of a system of vertical combs. Then the product is scattered on the product pouring conveyor. From the product pouring conveyor the food product drops on straight belt conveyor*, which carries pizza bases.

Straight belt conveyor* mentioned above is a separate device not described in this manual.

Batter dosing

Application: The machine is used in the production of pizzas, dumplings, sweets and other production requires precise dispensingof food products.

Structure: The structure is made of stainless steel. Dispenser is equipped with microprocessor control and an adequate number of metering pumps and dispensing nozzle adapted to the appropriate type of production.

How it works: The machine dispenses precisely for example sauce for base of pizza, a thick stuffing on ribbon of dough for the production of dumplings or whole, intact fruit.

Dispensers design individually according to customer needs.

Round Section Cooking Boiler for Chocolate with Mechanical Mixer

Applications: Cooking boiler with a mixer is used for melting chocolate. The structure is made of stainless steel, bunded heating system, filled with heating oil.

Features: Microprocessor controlled to adjust the charge temperature, temperature of oil jacket, switching time, the time of boiler operation, stirring the chocolate with variable speed propeller, the drain valve 2 “, the infusion of water, isolated design, stainless steel outer casing.

Fish washing machine

Application: The machine is used for emptying barrels with salted fish, then rinse the fish from spices used during the salting. Used in fish processing plants and distributors of salted fish.

Structure: The structure is made of stainless steel, equipped with a device draining barrels of salted fish to the tank.

How it works: The fish from the tank with brine is transported to the substituted containers or receiving conveyor. Nozzle system spray rinse fish using filtered brine from barrels. Rinsed fish can be used for further production or trade.

Washing and separating machine for vegetables

Application: Washer-separator is designed for washing potatoes, carrots, beets and other root vegetables.

How it works: Root vegetables for the washing and separation of stones goes through the chute to the drum stones separator. Stones sink to the bottom of the drum and the inner coils are transported to the trash. The rotating drum with the basket, using grabs throws stones at the gutter outlet. The further process of washing vegetables takes place in the back of the cabinet. As a result of pushing by the paw, mutual friction and the action of water, dirt falling by the the bottom of the rod into the gutter, where it is excreted in a continuous manner. While clean vegetables are scraped at the final conveyor where they are transported outside the machine.

Shredder packaging

Application: Shredder is used to destroy the paper packaging food products containing free flowing. After a break ofbags machine separates valuable food product from damaged bags.

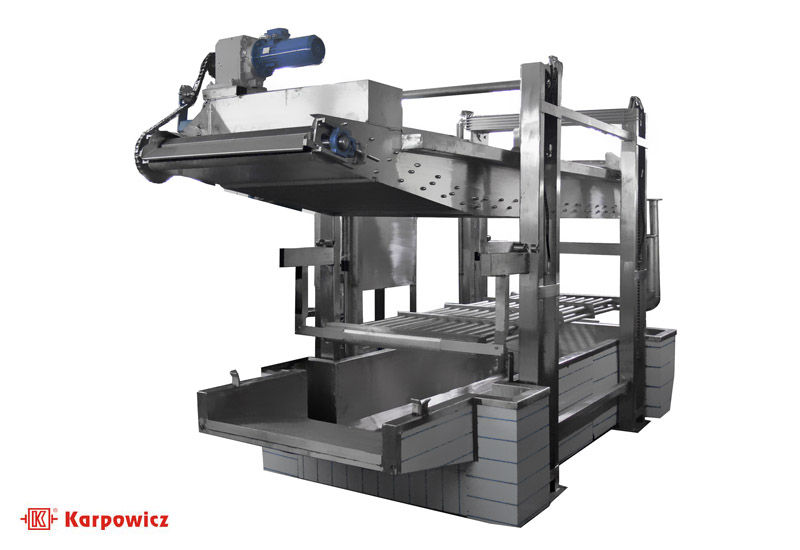

French fries frying machine

Application: The device is intended for frying French fries.

How it works: Raw, or pre-fried chips get into the hopper to the conveyor. Conveyor transports them into the appropriate immersionalong the machine. After completing the process of frying chips leave the machine. The degree of frying depends on the speed ofthe feed conveyor.

Water-fish separator

Application: The machine using pump transports the fish from the holds of fishing vessels to warehouse.

How it works: The pumped fish with water are separated from liquids in controlled quantities and fed to storage boxes.

The lifting conveyor type Z

Proper usage: Elevating Conveyor Belt type Z is designed to transport small fish as a part of food processing cycle and to drain the excess of water from them.

Working principle: Elevating Conveyor Belt type Z has a water container (basin) to which the water with product (small fish) is poured. The product is moved by catching components of conveyor belt. Belt is attached to two shafts: drive shaft makes it move and the other shaft makes it turn around. Drive shaft is moved by electric engine. Belt with use of catching component removes fish from basin removing the excess of water. Then product is transported upwards under a steep angle to appropriate height where it is passed to another device in the production process.

Stuffing pump with hopper, type: PFK

Purpose: device is used to pump the product contained in the hopper [e.g stuffing, sauce] to any other device [e.g cooking boiler, stuffing mixer etc.]

Equipment: feed hopper, control panel [variable speed control of pump rotations], feed hose – length of up to 10 m, stainless steel construction on wheels with brakes.

Main advantages:

– transportation of the product at the distance/height up to 10 m without affecting the structure of the stuffing;

– possibility of transporting the stuffing to multiple receivers;

– small overall dimensions and easy to move construction ;

– ease of maintaining hygiene [hose on quick coupling, opening hopper etc.]

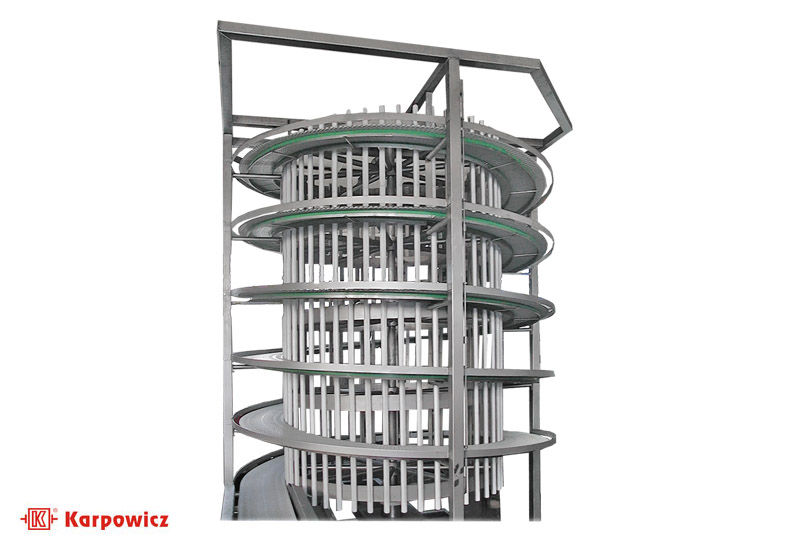

Spiral conveyor

Application: Spiral conveyor is used to move material from the conveyor belts at different heights.

Material return belt conveyor

Assignment: Material return belt conveyor is assigned for transport of food products. The device is made of materials with certificates permitting for contact with food products. The device is fitted for operation in connection with food products dosing machine. Both machines have common electrical circuit and control circuit on the dosing machine switch box.

Principle of operation: The machine conveys food products on straight line. Carrier is made of polyurethane belt, stretched between driving shaft (drum motor) on one side and on roller from another side. The conveyor is driven by drum motor. Conveyed material drops to container placed on container shelf.

Inclined conveyor

Application: The machine is part of the conveyors unit returning the raw material.Conveyor designed for the transport food products. This device is made of materials with a certificate allowing them to contact with food.

Conveyor with kneading roller

Application: The machine is part of the processing line for pizza. Used for rolling pizza bottoms in order to achieve the appropriate thickness.

Conveyor to transfer material to the top

Application: The machine is part of the conveyors unit returning the raw material.Conveyor designed for the transport food products. This device is made of materials with a certificate allowing them to contact with food.

Belt conveyor with water spray

Assignment: Belt conveyor with water spray is a machine composing part of a line for belt-system pizza production. This device is assigned for uniform spraying of water on pizzas that are moved by belt conveyor.

Principle of operation: Pizzas moved by the belt conveyor are sprayed with water by means of nozzles. Excess of water flows to the tank.

Modular conveyor for fish fillets

Proper usage: Modular Transporter is designed to transport fish fillets trough the food processing cycle.

Working principle: Modular Transporter moves product (fish fillets) in a straight line. The product is moved by the modular conveyor belt. Belt is attached to two shafts: drive shaft makes it move and the other shaft makes it turn around. Drive shaft is moved by electric engine.

Straight belt conveyor group for food products

Assignment: Straight belt conveyor is an apparatus assigned for moving products within section of production line. Since the device is made of materials with certificates permitting for contact with food, the conveyor may be applied for moving food products.

Principle of operation: The machine conveys food products on straight line. Carrier is made of polyurethane belt, stretched between driving shaft on one side and on return roller from another side. The conveyor is driven by electrical motor with reduction gear.

Ice water generator

Purpose: chiller is a device used to cool running water to a temperature of about 1 ° C.

Design: The chiller is a mobile device (two of the four driving wheels have a brake), made of stainless steel. The device is equippedwith a range of electronic security: protection against phase loss, protection before running the unit without a connected water andlack of water in the tank (pressure sensor).