Product Catalog

Cheese cube machine

Application: slicer is used for cutting blocks of cheese with maximum dimensions: Width-400 mm, height-300 mm, and cheese in the shape of a cylinder with a maximum diameter 100 mm, for cube measuring 5x5x5 cm. This allows, in turn, other devices to form a shavings. Used, among others for the production of pizzas, baguettes, cheese blocks.

Construction and operation: The design of the device is made of stainless steel.

The device consists of two units:

Unit of conveyor feeding;

Horizontal cutting section – transverse unit of knives, powered by a hydraulic cylinder;

Vertical cutting section – guillotine powered by a hydraulic cylinder;

Hydraulic system;

Electrical control;

The device works automatically. Cycle of action:

Conveyor moves the blocks of cheese with a preset distance (10 to 200 mm)

Vertical cutting section cut from blocks of pre-programmed slice thickness

Horizontal section cut transversely cut off slice into cubes 50x50x (10-200) mm

Cheese cut into cubes falls to dump raw gutter.

Back to Action 1

Food products dosing machine

Appliance: Food stuff batcher is a machine composing part of a line for belt-system pizza production. This device is assigned for pouring shredded food products, at a uniform rate, on the surface of pizza bases that are moved by straight belt conveyor*.

Principle of operation: The machine spreads the food product on the feeding conveyor by means of a system of vertical combs. Then the product is scattered on the product pouring conveyor. From the product pouring conveyor the food product drops on straight belt conveyor*, which carries pizza bases.

Straight belt conveyor* mentioned above is a separate device not described in this manual.

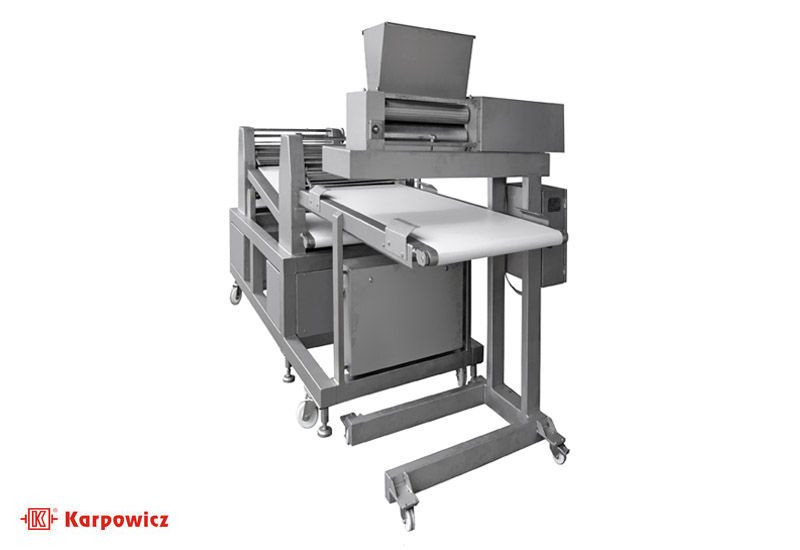

Batter dosing

Application: The machine is used in the production of pizzas, dumplings, sweets and other production requires precise dispensingof food products.

Structure: The structure is made of stainless steel. Dispenser is equipped with microprocessor control and an adequate number of metering pumps and dispensing nozzle adapted to the appropriate type of production.

How it works: The machine dispenses precisely for example sauce for base of pizza, a thick stuffing on ribbon of dough for the production of dumplings or whole, intact fruit.

Dispensers design individually according to customer needs.

Shredder packaging

Application: Shredder is used to destroy the paper packaging food products containing free flowing. After a break ofbags machine separates valuable food product from damaged bags.

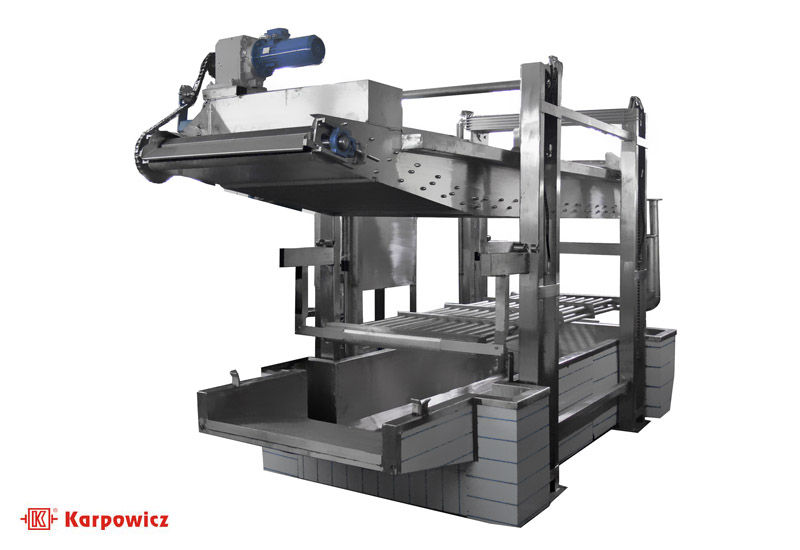

French fries frying machine

Application: The device is intended for frying French fries.

How it works: Raw, or pre-fried chips get into the hopper to the conveyor. Conveyor transports them into the appropriate immersionalong the machine. After completing the process of frying chips leave the machine. The degree of frying depends on the speed ofthe feed conveyor.

Water-fish separator

Application: The machine using pump transports the fish from the holds of fishing vessels to warehouse.

How it works: The pumped fish with water are separated from liquids in controlled quantities and fed to storage boxes.

Modular conveyor for fish fillets

Proper usage: Modular Transporter is designed to transport fish fillets trough the food processing cycle.

Working principle: Modular Transporter moves product (fish fillets) in a straight line. The product is moved by the modular conveyor belt. Belt is attached to two shafts: drive shaft makes it move and the other shaft makes it turn around. Drive shaft is moved by electric engine.